Pleating process

Pleated

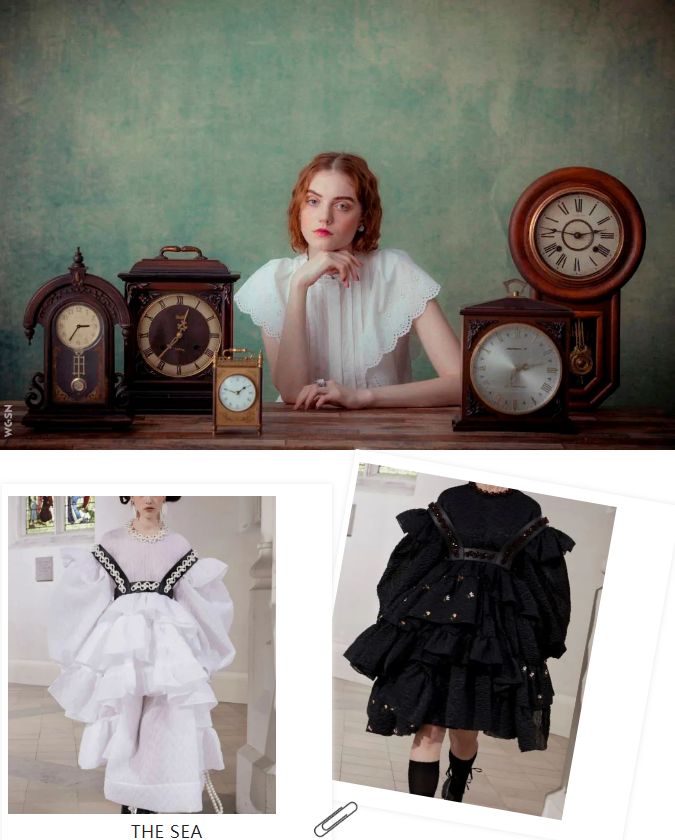

The garment creasing process is a production process in which a series of folds and shapes are extruded from the garment fabric under suitable temperature, humidity and pressure with a manual iron or professional machinery and equipment to meet the requirements of the garment design effect. The garment pleating process is widely used in the design and modeling of women’s clothing, and the pleating form is varied.

Garment pleating is the pleating treatment of fabrics and pieces. Generally, there are row pleats, fan-shaped pleats, flower pleats, three-dimensional pleats, bow pleats, toothpick pleats, wire pleats, etc. Generally, it is processed into the desired pleat row by a high-temperature pleating machine. Some pleating rows cannot be processed by a pleating machine, and must be manually folded and then subjected to steam treatment. Pleating is suitable for all kinds of clothing fabrics, cloth, silk, cut pieces, home textiles, georgette, etc., whether it is suitable or not needs to be tested.

Pleating method

Machine pleating: It is to use a professional pleating machine to pleat the fabric. Generally, the regular pleating styles such as pleats, I-shaped pleats, chaotic pleats, and accordion pleats are all machine pleating.

Manual pleating: Simply put, all the pleating styles that cannot be done by machines belong to the category of manual pleating. Like sun pleats, straight pleats, chicken scratches, etc., there are also some large pleats or I-shaped pleats, which are beyond the size of machine pleats, and are also pleated by hand. The cost of manual pleating is higher than that of machine pleating because of low production efficiency and high process requirements.

Fold category

1.Parallel pleat

Flat folds are one fold and one fold into a flat, with inverted pleats. Flat folds are the most common and common folds used in clothing decoration. It refers to the machine flat fold, and the main dimension elements are divided into pleat bottom and pleat surface, the pleat bottom is the covered part, and the pleat surface is the leaked part.

2.bow pleat

Bow pleats are divided into full bow pleats and bow flat pleats. The full bow pleat is composed of multiple bow pleats, and the bow flat pleat is a pattern composed of several bow pleats and several flat pleats. The main dimension elements of the bow pleat are divided into the bow bottom and the bow face, the bow bottom is the covered part, and the bow face is the visible part.

3.Toothpick pleats

Toothpick pleats, as the name suggests, are pleats the size of a toothpick, which stand upright and are not inverted, also called small three-dimensional pleats. Toothpick pleats have only one main size, the pleat height. The pleat height made by this machine ranges from 0.15 to 0.8 cm.

4.Bamboo leaf pleats

Bamboo leaf pleats, as the name suggests, are patterned pleats like bamboo leaves. Bamboo leaf pleats are divided into full bamboo leaf pleats and flower-shaped bamboo leaf pleats.

The whole bamboo leaf pleat is a pleat composed entirely of herringbone patterns, and the flower pattern bamboo leaf pleat is a pattern pleat composed of several herringbone patterns plus several flat pleats or neutral spaces. Bamboo leaf pleats, the main dimension elements of bamboo leaf surface and bamboo leaf bottom.

5.wavy pleats

Wavy pleats are pattern pleats like water ripples.

Wavy pleats are pleats made with a wave knife, and the knife needs to be changed every time a new sample is made, which is time-consuming. So sampling is slow. For wavy pleats, the main dimension elements are the wavy bottom and the wavy surface. It is suitable for making some slightly elastic chemical fiber fabrics.

6.Wire pleats

Wire pleats are wrinkles extruded by steel wires, which are somewhat similar to toothpick wrinkles, but with more horizontal wire prints.

Wire pleats are arranged by many steel wires. The spacing between the steel wires is 1 cm, which can be a multiple of 1 cm. The steel wires can be removed at will, and local steel wire wrinkles can be made. Mainly suitable for polyester, chemical fiber fabrics, widely used in chiffon fabrics, the best setting effect

7.Scalloped pleats

Fan-shaped pleats, also called sun pleats, are pleats that can be folded and unfolded like a fan. Fan-shaped pleats are divided into machine fan-shaped pleats and manual fan-shaped pleats. Machine fan-shaped pleats can only do some ordinary fan-shaped pleats.

The fabrics made of different sizes are relatively flexible, and they can do anything and are widely used. Manual fan-shaped pleats are pleats formed by clamping the fabric with two layers of molds and setting it at a high temperature for 1 to 1.5 hours.

Scalloped pleats, the main size factors are the size of the upper mouth and the lower mouth.

8.flower sun pleats

Flower-shaped sun pleats are fan-shaped pleats with flowers.

The patterned sun pleats are all hand-made with patterned molds, and even the finished pieces are also patterned sun pleats.

The hand-made pattern pleat mold is slow, the large-scale delivery cycle is long, and the mold is easy to break, so it needs to provide a longer supply period.

9.Accordion pleats

Organ pleats are also called large three-dimensional pleats, which are pleats that can be closed and unfolded like an organ. It is different from the fan-shaped pleats, which are small at the top and large at the bottom, while the organ is the same size as the top and bottom.

Organ pleats are divided into machine organ pleats and manual organ pleats. Machine organ pleats are generally made of cloth, and there are many curtains, while handmade organ pleats are more common for clothing pieces. Manual accordion pleats are pleats formed by sandwiching the fabric with two layers of film and setting it at a high temperature for 1 to 1.5 hours. The main dimension factor is the pleat height.

10.Hand pleated

Manual pleats are large flat pleats, downwind pleats, and inverted pleats.

Manual pleating is because the size is large, the bottom of the pleat is more than 2 cm or the pleated surface is more than 3.5 cm, it can only be done by making a mold, put the fabric into the mold and put it in the tablet machine and press it at high temperature for more than ten seconds.

The production efficiency of manual pleated bulk goods is not high, mainly depends on the speed of labor, so the cycle will be longer.

11.Garment ruffled

Random pleats are irregular pleats, which are divided into machine random folds and manual random folds. Machine random pleats are irregular pleats formed by pressing one or two or three times with a machine. Hand ruffled pleats are created by hand grabbing pleats, wrapping them in paper, and then setting them at high temperature for one or two hours. The ruffles can be cut out or made into ruffles.

Post time: Dec-06-2022